Simulation of behavioural modification effects on multiphase flows

- Academic lead

- Michael Fairweather (Chemical and Process Engineering)

- Industrial lead

- Martyn Barnes, Sellafield Ltd

- Co-supervisor(s)

- David Harbottle (Chemical and Process Engineering)

- Project themes

- Energy and Transport, Industrial Processes, Underpinning Methods for Fluid Dynamics

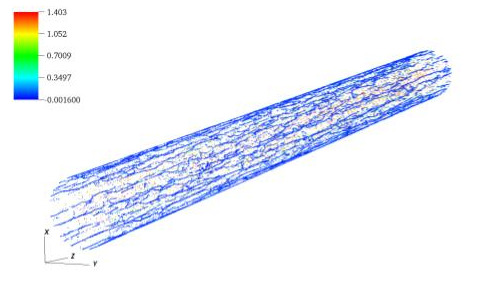

Direct numerical simulation coupled to an interface tracking technique, for small numbers of particles, and Lagrangian particle tracking, for more realistic numbers of particles, will be used to investigate the behaviour of particles in fluid flows. The impact of behavioural modification techniques (such as the use of plasticisers, fluid pH and density changes, and responsive/smart fluids) on their agglomeration and break-up, as well as their tendency to deposit and re-suspend within the flows, will be studied. The work proposed will lead to fundamental insights into the behaviour of particles in ideal flows, as well as the particulate and carrier fluid properties that define the flow behaviour of realistic numbers of particles being transferred by continuous flow through pipes under a range of realistic conditions. The former will allow basic understanding of these flows and, in particular, how behavioural modification techniques impact particle-particle interactions, particle agglomeration and break-up, whilst the latter will provide realistic simulations that are able to predict the impact of a range of different plant and process conditions, slurry compositions and particle morphology on the flow behaviour of slurries. They will also provide benchmark solutions that are of value in testing the accuracy of the more pragmatic engineering approaches currently used in industry (which include simpler CFD techniques).

Figure: Instantaneous particle distribution with contour levels of particle non-dimensional streamwise velocity in a pipe showing particles preferentially concentrating in low speed streaks close to the pipe wall.