Optimizing the Drying Process in Battery Electrodes Using Lattice Boltzmann Method

- Academic lead

- Dr Masoud Jabbari, School of Mechanical Engineering, m.jabbari@leeds.ac.uk

- Co-supervisor(s)

- Dr Arash Rabbani, School of Computing, a.rabbani@leeds.ac.uk, Dr Alice Macente, School of Civil Engineering, a.macente@leeds.ac.uk, Dr Mark Wilson, School of Mechanical Engineering, M.Wilson@leeds.ac.uk

- Project themes

- Energy and Transport, Industrial Processes

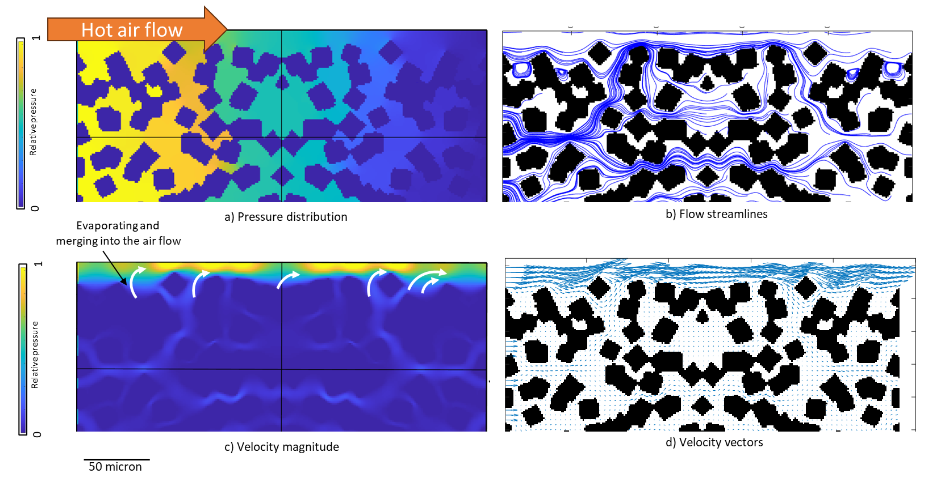

As the UK moves towards net-zero emissions, developing low-cost, high-energy density lithium-ion batteries (LIBs) is crucial. A major cost driver in LIB manufacturing is the slow, energy-intensive process of drying battery electrodes after coating them onto current collectors. This drying process impacts material distribution and pore structure, directly influencing battery performance. In this project, we will model the drying dynamics combining the 3D micro-computed x-ray images with Lattice Boltzmann method (LBM) to efficiently solve the multiphysics equations governing the process. We will be using well-documented open-source packages such as LBMPY which is written in python language. Successful completion of this project will equip the student for the future simulation roles in the expanding market of electric cars and battery-driven devices. Below, you can see a simplified 2D demonstration of the process considering a Newtonian fluid with Bhatnagar Gross and Krook (BGK) collision model.