Use of Particle Image Velocimetry for Assessing Burning Characteristics of Novel Fuels for Advanced Internal Combustion Engines

- Academic lead

- Derek Bradley (Mechanical Engineering)

- Industrial lead

- Roger Cracknell, Shell Global Solutions

- Co-supervisor(s)

- Malcolm Lawes (Mechanical Engineering), Junfeng Yang (Mechanical Engineering), Alison Tomlin (Chemical and Process Engineering)

- Project themes

- Microflows & heat transfer, Reacting flows, mixing and safety

In spite of increasing vehicle electrification, most road vehicles will continue to have an internal combustion engine (ICE), albeit as part of a hybrid powertrain. There will be increasing focus on reducing the carbon intensity of fuels for ICEs and advanced biofuels are likely to be extremely important, as envisaged in the recent Shell Sky Scenario, which illustrates a technically possible, but challenging pathway for society to achieve the goals of the Paris Climate Change Agreement

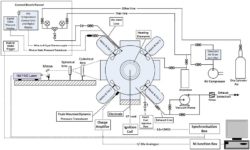

One of the key requirements for ultra-efficient, low-emisions engines will be fuel combustion operability when the fuel/air mixture is ultra-lean. Leeds have recently started using the Particle Image Velocimetry technique to study flame development in the unique stirred explosion vessel, in the School of Mechanical Engineering. Four variable speed fans control the rms turbulent velocity of a fuel/air mixture, and hence the turbulent burning velocity. Initially, increasing the rms velocity increases the rate of burning, but if it becomes too high, the burning can be quenched, particularly when operating very lean. The objective of this work is to use the PIV technique to characterise ultra-lean combustion for a range of advanced fuels

Diagramatic Representation of explosion vessel and PIV.