3D printing of liquid crystal elastomers

- Academic lead

- Dr Oliver Harlen, School of Mathematics, o.g.harlen@leeds.ac.uk

- Co-supervisor(s)

- Dr Devesh Mistry, School of Physics & Astronomy, d.a.mistry@leeds.ac.uk , Dr Mark Walkley, School of Computing, m.a.walkley@leeds.ac.uk, Professor Daniel Read, School of Mathematics, d.j.read@leeds.ac.uk

- Project themes

- Industrial Processes

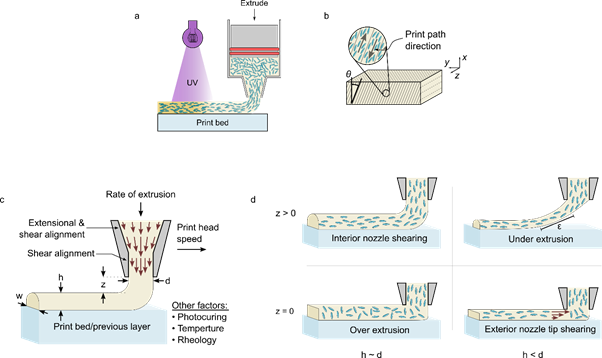

Liquid crystal elastomers (LCEs) are a new class of soft materials which have a myriad of potential uses due to their unique properties. Direct-Ink Writing (DIW) 3D printing provides a potential method to make large and highly complex devices from LCEs, but we need to first understand precisely how to control and optimise the extent of molecular order created in 3D printed devices. Order is dictated by a plethora of material properties and printing parameters such as temperature, ink viscosity, printing speed, and nozzle geometry.

In this project you will create a fluid dynamics model to understand how the molecular ordering created by the extrusion flow can be maximised in DIW printed LCE devices. The predictions of this model will be verifying against experimental tests of physically printed LCE devices.

Figure: a. Schematic of direct-ink writing of LCEs, where molecules are aligned through extrusion and then photo cross-linked into an elastomer. b. The direction of print-head movement dictates the molecular orientation. c and d Illustrations of the different parameters effecting molecular order of extruded LCO filaments.